Home>Technology and Computers>The Perfect Wire Gauge For A 30-Amp Breaker: Is 12 Gauge The Ultimate Solution?

Technology and Computers

The Perfect Wire Gauge For A 30-Amp Breaker: Is 12 Gauge The Ultimate Solution?

Published: January 29, 2024

Find out if 12 gauge wire is the ideal choice for a 30-amp breaker. Explore the perfect wire gauge for your electrical needs. Expert advice on technology and computers.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Regretless.com, at no extra cost. Learn more)

Table of Contents

Introduction

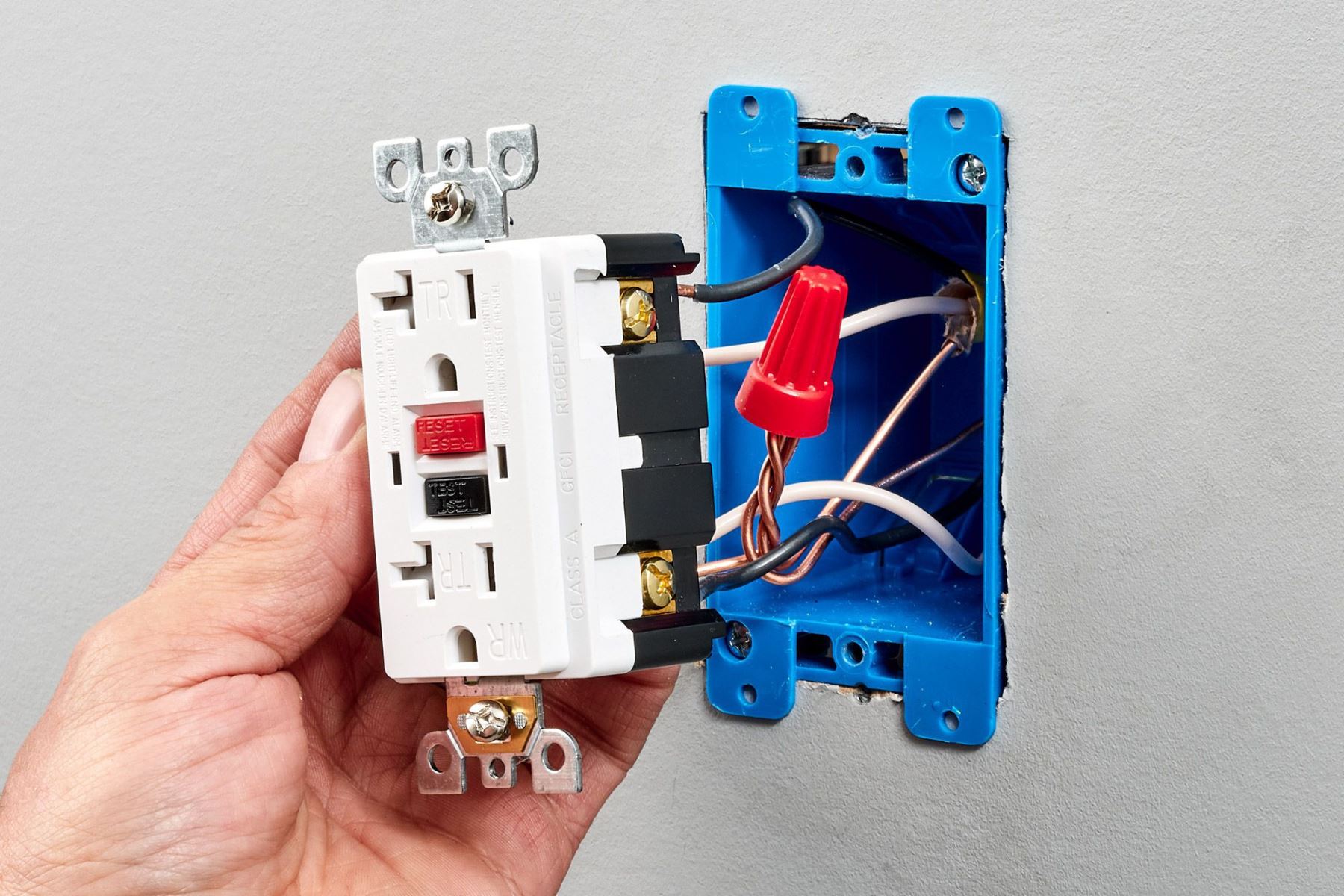

Selecting the appropriate wire gauge for a 30-amp breaker is crucial for ensuring the safe and efficient operation of electrical circuits. The wire gauge, also known as the wire size, plays a pivotal role in determining the electrical conductivity and the capacity to handle the current flow. When it comes to a 30-amp breaker, it's essential to choose a wire gauge that can effectively support this level of electrical load without overheating or causing safety hazards.

The process of selecting the ideal wire gauge involves considering various factors, including the electrical code requirements, the length of the wire run, the type of conductor material, and the specific application. Moreover, understanding the relationship between wire gauge and amperage is fundamental in making an informed decision. By delving into the intricacies of wire gauge and its correlation with amperage, individuals can gain valuable insights into the significance of choosing the right wire size for a 30-amp breaker.

In this comprehensive guide, we will explore the critical aspects of wire gauge selection for a 30-amp breaker, shedding light on the implications of using an incorrect wire size and the benefits of opting for the optimal gauge. Additionally, we will delve into the debate surrounding the suitability of 12-gauge wire for a 30-amp breaker, unraveling the complexities and considerations associated with this particular wire size. By unraveling these essential concepts, readers will gain a deeper understanding of the significance of wire gauge in electrical systems and the intricacies of selecting the perfect wire size for a 30-amp breaker.

Understanding Wire Gauge and Amps

Wire gauge, denoted by a numerical value, refers to the thickness or diameter of a wire. The gauge of a wire is inversely proportional to its diameter, meaning that a lower gauge number signifies a thicker wire. In the context of electrical systems, the wire gauge plays a critical role in determining the current-carrying capacity and electrical resistance of the wire. This, in turn, directly impacts the safety and efficiency of the electrical circuit.

Amps, short for amperes, represent the unit of measurement for electrical current. When selecting a wire gauge for a specific application, it is essential to consider the corresponding amperage, as the wire must be capable of safely carrying the electrical load without overheating. The relationship between wire gauge and amps is governed by the principle that thicker wires (lower gauge numbers) can accommodate higher amperage levels without experiencing excessive resistance or heat buildup.

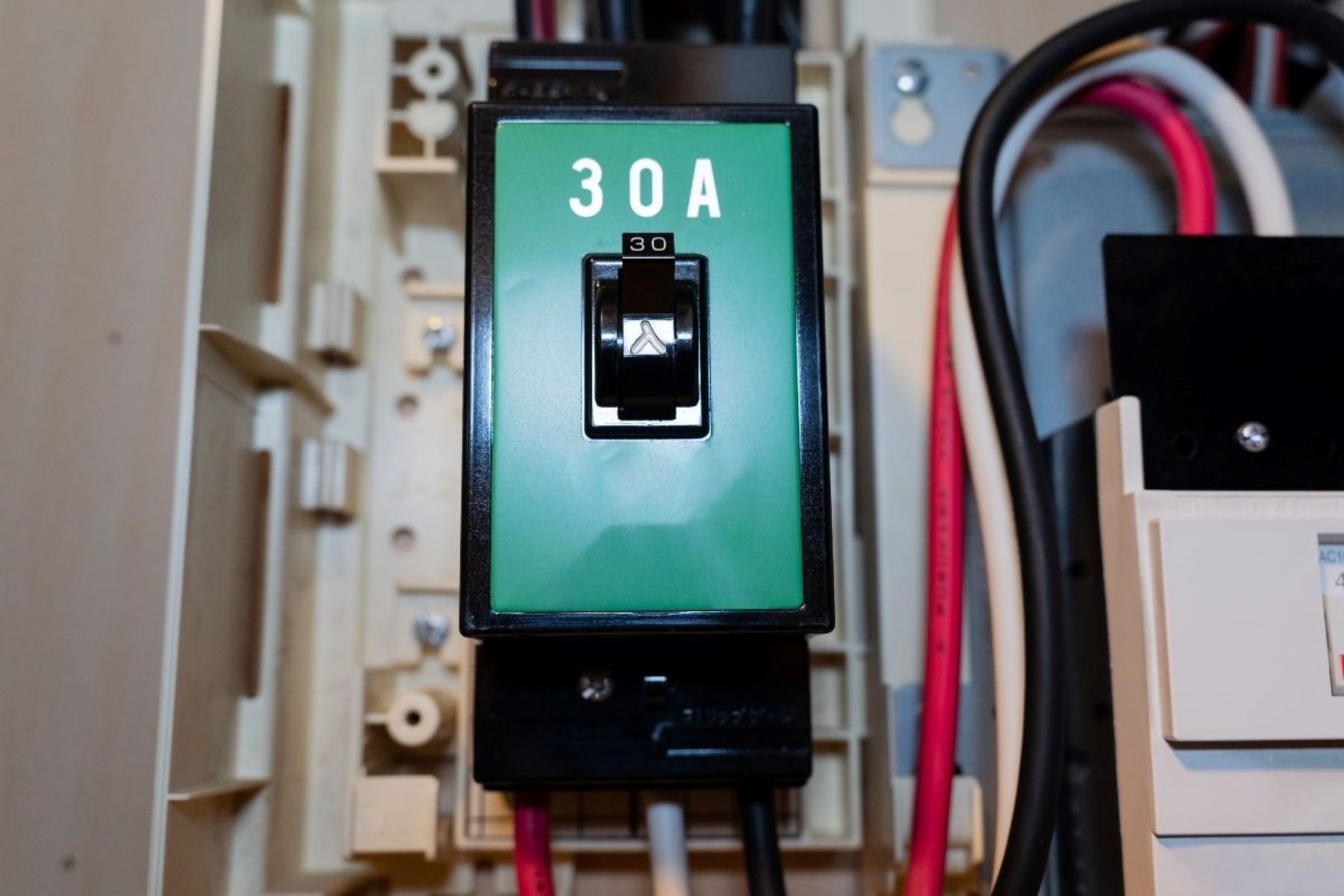

In electrical circuits protected by a 30-amp breaker, the wire gauge must be selected to match or exceed the maximum current-carrying capacity of 30 amperes. This ensures that the wire can effectively handle the electrical load without posing safety risks. Failure to use an appropriate wire gauge for a 30-amp breaker can result in overheating, voltage drops, and potential fire hazards, underscoring the critical importance of understanding the relationship between wire gauge and amps.

Moreover, the American Wire Gauge (AWG) system is commonly employed to standardize wire sizes for various applications, providing a numerical reference that correlates wire diameter with amperage capacity. As the AWG value decreases, indicating a thicker wire, the corresponding amperage rating increases. This standardized system facilitates the selection of the right wire gauge based on the specific amperage requirements, enabling individuals to make informed decisions while adhering to safety regulations and electrical codes.

Understanding the nuances of wire gauge and its correlation with amperage is fundamental for individuals involved in electrical installations and maintenance. By grasping the significance of selecting an appropriate wire size in relation to the amperage of the electrical circuit, professionals and enthusiasts alike can uphold safety standards, optimize electrical performance, and mitigate potential risks associated with inadequate wire sizing.

The Importance of Choosing the Right Wire Gauge for a 30-Amp Breaker

Selecting the correct wire gauge for a 30-amp breaker holds paramount significance in the realm of electrical installations. The wire gauge directly influences the ability of the electrical circuit to accommodate the 30-amp current load without succumbing to overheating or voltage drops. Inadequate wire sizing can lead to detrimental consequences, including fire hazards, equipment damage, and compromised electrical performance. Therefore, the importance of choosing the right wire gauge for a 30-amp breaker cannot be overstated.

One of the primary reasons for prioritizing the selection of the appropriate wire gauge is to ensure safety and compliance with electrical codes and regulations. Electrical systems are designed with specific amperage requirements, and the wire gauge must align with these parameters to maintain safe operation. Using an undersized wire for a 30-amp circuit can result in excessive resistance, leading to heat generation and potential insulation degradation. Conversely, employing an oversized wire may lead to unnecessary expenses and impractical installations. By adhering to the recommended wire gauge for a 30-amp breaker, individuals can uphold safety standards and regulatory compliance, mitigating the risks associated with electrical malfunctions.

Furthermore, the selection of the right wire gauge directly impacts the efficiency and reliability of the electrical circuit. Inadequate wire sizing can lead to voltage drops, diminishing the performance of connected devices and equipment. This can be particularly problematic in scenarios where consistent and stable voltage levels are imperative, such as in industrial machinery or sensitive electronic systems. By choosing the optimal wire gauge for a 30-amp breaker, individuals can ensure that the electrical circuit operates at its full potential, delivering reliable power without compromising performance.

Moreover, the economic and practical implications of selecting the right wire gauge cannot be overlooked. Utilizing the correct wire size for a 30-amp breaker minimizes unnecessary material costs and facilitates efficient use of resources. Additionally, it streamlines the installation process, reducing complexities and ensuring a streamlined electrical setup. By prioritizing the selection of the appropriate wire gauge, individuals can optimize the overall cost-effectiveness and practicality of electrical projects, thereby enhancing the long-term sustainability and functionality of the electrical system.

In essence, the importance of choosing the right wire gauge for a 30-amp breaker transcends mere technical considerations; it encompasses safety, compliance, efficiency, and practicality. By recognizing the pivotal role of wire gauge in electrical installations, individuals can make informed decisions that uphold the integrity and performance of electrical systems, fostering a secure and reliable operational environment.

Is 12 Gauge the Ultimate Solution for a 30-Amp Breaker?

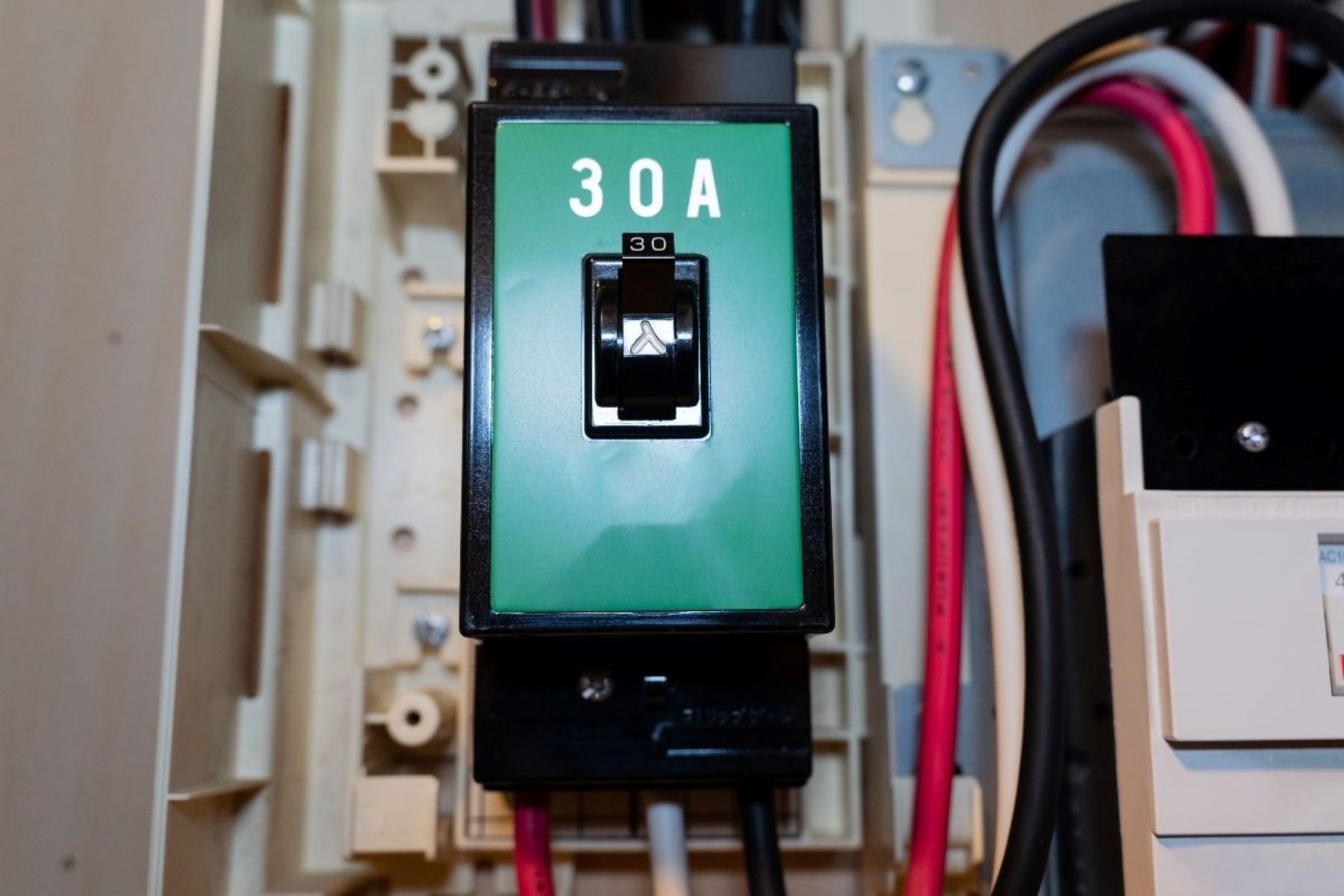

The debate surrounding the suitability of 12-gauge wire for a 30-amp breaker has sparked considerable discussion within the realm of electrical engineering and installations. The American Wire Gauge (AWG) system designates 12-gauge wire as a common choice for residential electrical wiring, primarily employed in circuits with 20-amp breakers. However, the question arises: can 12-gauge wire be utilized as the ultimate solution for a 30-amp breaker?

While 12-gauge wire possesses notable attributes, including a substantial current-carrying capacity and widespread availability, its application in conjunction with a 30-amp breaker warrants careful consideration. The AWG system dictates that 12-gauge wire is rated for a maximum continuous current of 20 amperes, aligning with the standard utilization in 20-amp circuits. However, the utilization of 12-gauge wire in a 30-amp circuit exceeds its designated amperage rating, potentially leading to safety hazards and non-compliance with electrical codes.

In the context of a 30-amp breaker, the National Electrical Code (NEC) stipulates that a minimum wire size of 10 AWG must be employed to accommodate the 30-amp current load effectively. This requirement is rooted in safety considerations and is integral to ensuring the secure and reliable operation of the electrical circuit. Deviating from the prescribed wire size guidelines can compromise the structural integrity of the circuit, leading to overheating, insulation degradation, and heightened fire risks.

While some may contemplate the feasibility of using 12-gauge wire with a 30-amp breaker due to its perceived robustness, it is imperative to uphold the prescribed standards and adhere to the established wire size recommendations. Doing so not only aligns with safety protocols and regulatory requirements but also safeguards the electrical system against potential hazards and performance limitations.

In essence, while 12-gauge wire exhibits commendable characteristics, it is not the ultimate solution for a 30-amp breaker. Adhering to the prescribed wire size guidelines, such as employing 10-gauge wire for a 30-amp circuit, is pivotal in upholding safety standards, ensuring regulatory compliance, and fostering the efficient and secure operation of electrical circuits. By prioritizing the selection of the appropriate wire gauge in accordance with the prescribed amperage requirements, individuals can fortify the integrity and reliability of electrical installations, underscoring the critical importance of meticulous wire size selection in the realm of electrical engineering.

Factors to Consider When Choosing the Perfect Wire Gauge

When embarking on an electrical installation project or seeking to upgrade existing circuits, the selection of the perfect wire gauge entails a comprehensive evaluation of various critical factors. By meticulously considering these elements, individuals can make informed decisions that align with safety standards, regulatory requirements, and the specific operational demands of the electrical system.

-

Amperage Requirements: Understanding the amperage requirements of the electrical circuit is fundamental in determining the appropriate wire gauge. The designated amperage, often dictated by the connected devices and equipment, serves as a guiding parameter for selecting a wire size that can safely accommodate the anticipated current load.

-

Wire Length and Resistance: The length of the wire run and its inherent resistance are pivotal considerations in wire gauge selection. Longer wire runs introduce higher resistance, potentially leading to voltage drops and diminished electrical performance. By accounting for the wire length and its impact on resistance, individuals can choose a wire gauge that mitigates these challenges, ensuring consistent and stable power delivery.

-

Material and Conductor Type: The material composition and conductor type of the wire play a significant role in determining its current-carrying capacity and suitability for specific applications. Copper and aluminum are commonly utilized conductor materials, each with distinct attributes that influence their ampacity and performance characteristics. By evaluating the material and conductor type, individuals can make informed decisions regarding the optimal wire gauge for the intended electrical circuit.

-

Environmental Considerations: Environmental factors, such as temperature fluctuations and exposure to moisture or corrosive elements, can influence the selection of the perfect wire gauge. In environments prone to elevated temperatures or adverse conditions, individuals must prioritize wire gauges that exhibit resilience and durability, ensuring long-term reliability and safety.

-

Regulatory Compliance and Electrical Codes: Adhering to regulatory standards and electrical codes is non-negotiable in electrical installations. The National Electrical Code (NEC) and other applicable regulations provide specific guidelines for wire sizing based on amperage requirements, circuit type, and environmental considerations. By aligning with these regulatory provisions, individuals can uphold safety standards and mitigate potential risks associated with non-compliance.

-

Future Expansion and Load Growth: Anticipating future expansion and potential load growth is crucial when selecting the perfect wire gauge. By factoring in potential increases in electrical demand and the need for additional devices or equipment, individuals can preemptively choose a wire gauge that accommodates these future requirements, minimizing the need for extensive rewiring or upgrades.

-

Cost-Efficiency and Practicality: Balancing cost-efficiency and practicality is essential in wire gauge selection. While thicker wire gauges offer higher ampacity and lower resistance, they may entail higher material costs and installation complexities. Conversely, employing excessively thin wire gauges may compromise safety and long-term performance. By striking a balance between cost-effectiveness and practicality, individuals can optimize the overall value and functionality of the electrical system.

By meticulously evaluating these factors, individuals can navigate the complexities of wire gauge selection, ensuring that the chosen wire size aligns with safety standards, operational requirements, and regulatory provisions. This comprehensive approach fosters the establishment of secure, efficient, and reliable electrical circuits, underscoring the critical importance of thoughtful consideration in the realm of wire gauge selection.

Conclusion

In conclusion, the selection of the perfect wire gauge for a 30-amp breaker is a pivotal aspect of electrical installations, encompassing multifaceted considerations that directly impact safety, performance, and regulatory compliance. By delving into the intricacies of wire gauge and its correlation with amperage, individuals can gain valuable insights into the significance of choosing the right wire size for a 30-amp breaker.

The critical importance of selecting the appropriate wire gauge for a 30-amp breaker cannot be overstated. It directly influences the safety, efficiency, and reliability of electrical circuits, underscoring the imperative nature of meticulous wire size selection. Moreover, the economic and practical implications of choosing the right wire gauge are noteworthy, as it streamlines the installation process, reduces complexities, and optimizes the overall cost-effectiveness of electrical projects.

The debate surrounding the suitability of 12-gauge wire for a 30-amp breaker highlights the necessity of adhering to prescribed wire size guidelines. While 12-gauge wire possesses commendable characteristics, it is not the ultimate solution for a 30-amp breaker. Upholding safety standards, regulatory compliance, and the efficient and secure operation of electrical circuits necessitates prioritizing the selection of the appropriate wire gauge in accordance with the prescribed amperage requirements.

Furthermore, the comprehensive evaluation of critical factors, such as amperage requirements, wire length and resistance, material and conductor type, environmental considerations, regulatory compliance, and future expansion, is fundamental in choosing the perfect wire gauge. By meticulously considering these elements, individuals can make informed decisions that align with safety standards, regulatory requirements, and the specific operational demands of the electrical system.

In essence, the process of selecting the perfect wire gauge for a 30-amp breaker demands meticulous attention to detail, a comprehensive understanding of electrical principles, and a steadfast commitment to safety and regulatory compliance. By navigating the complexities of wire gauge selection and prioritizing the adherence to prescribed standards, individuals can fortify the integrity and reliability of electrical installations, fostering a secure and efficient operational environment.