Home>Technology and Computers>The Purpose Of Holes In US Power Plugs And The Difference In Plug Sizes Compared To Europe

Technology and Computers

The Purpose Of Holes In US Power Plugs And The Difference In Plug Sizes Compared To Europe

Published: February 20, 2024

Learn about the purpose of holes in US power plugs and the differences in plug sizes compared to Europe. Explore the technology and computer aspects of power plug design.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Regretless.com, at no extra cost. Learn more)

Table of Contents

Introduction

Power plugs are an essential component of our daily lives, enabling us to connect our electronic devices to a power source effortlessly. While they may appear simple at first glance, power plugs actually serve a crucial purpose in ensuring the safe and efficient transmission of electricity to our devices. Understanding the intricacies of power plugs, including the purpose of the holes in US power plugs and the differences in plug sizes compared to those in Europe, can provide valuable insights into the world of electrical engineering and international standards.

In this article, we will delve into the fascinating realm of power plugs, unraveling the mysteries behind their design and functionality. By exploring the unique features of US power plugs and comparing them to their European counterparts, we aim to shed light on the diverse approaches to electrical connectivity across different regions. Join us on this enlightening journey as we uncover the significance of power plug design and the impact it has on our daily interactions with technology.

The Purpose of Holes in US Power Plugs

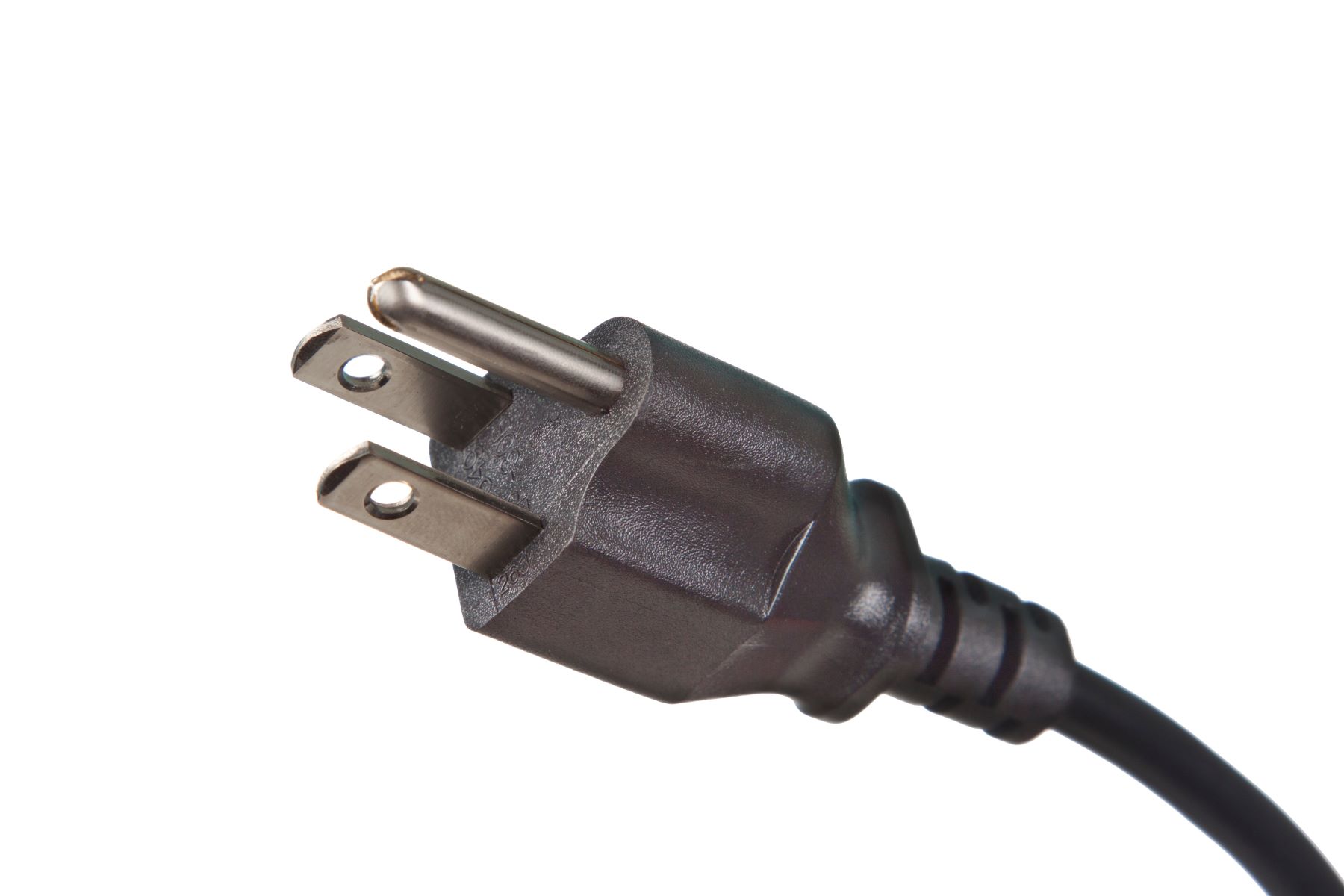

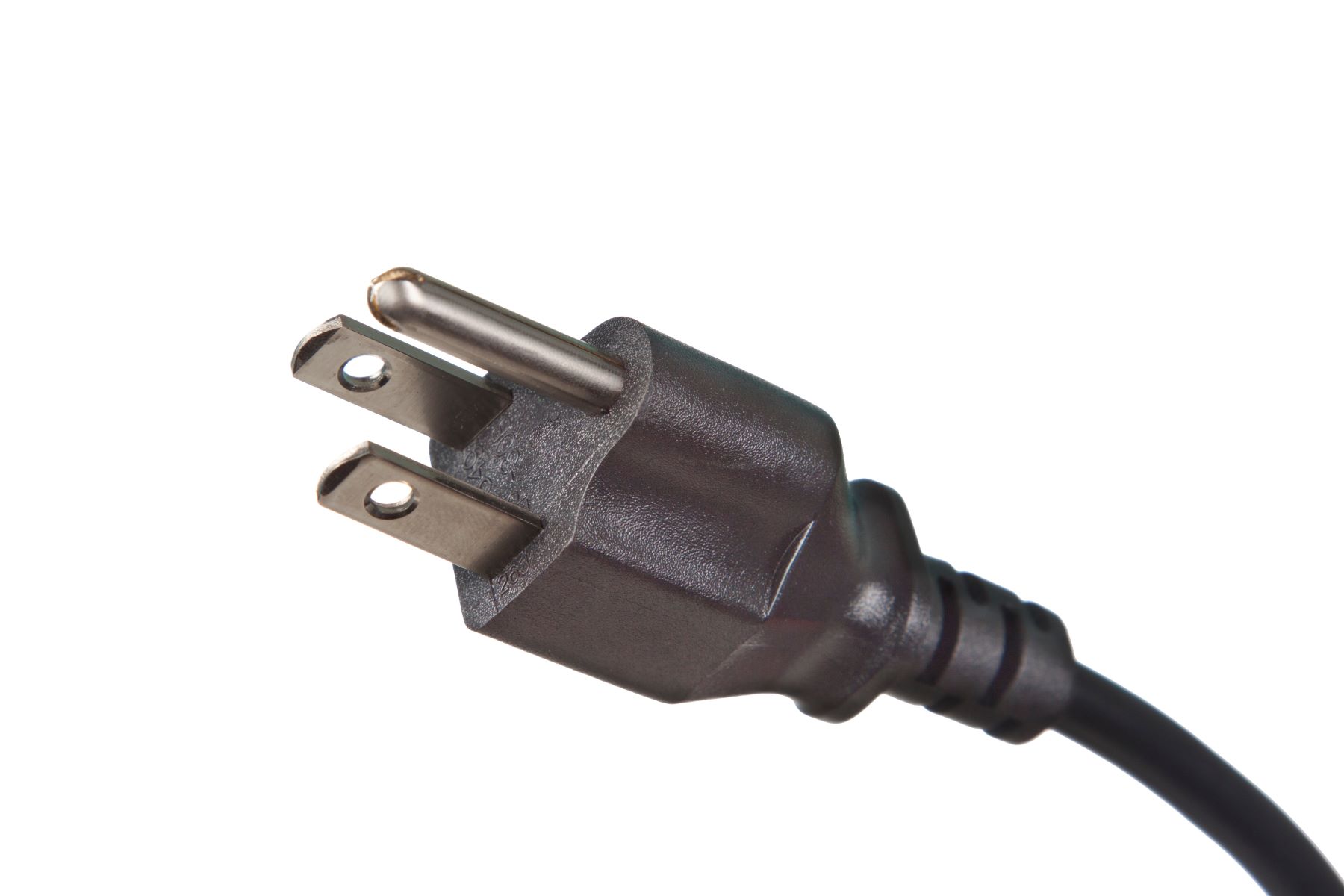

US power plugs, characterized by their distinctive two-pronged design with small holes located near the base, serve a crucial role in ensuring the safety and functionality of electrical connections. These holes are strategically incorporated into the plug's structure to address specific engineering and safety considerations, reflecting the meticulous design process behind these ubiquitous electrical components.

The primary purpose of the holes in US power plugs is to facilitate the implementation of a safety feature known as the "polarized plug." This design ensures that the plug can only be inserted into a power outlet in one orientation, effectively reducing the risk of electrical shock and enhancing user safety. The smaller prong, often referred to as the neutral prong, is intended to be inserted into the corresponding wider slot in the outlet, while the larger prong, known as the hot prong, is designed to fit into the narrower slot. The presence of the holes allows for the integration of a corresponding pair of protrusions within the outlet, ensuring that the plug can only be inserted in the correct orientation. This polarization mechanism minimizes the likelihood of accidental contact with live electrical components, thereby mitigating potential hazards.

Furthermore, the holes in US power plugs also enable the implementation of grounding features in certain plug designs. Grounded plugs, denoted by the inclusion of a third prong, rely on the presence of these holes to align with grounding contacts within the outlet. This grounding configuration serves to divert excess electrical current away from the connected device, providing an additional layer of protection against electrical faults and ensuring the safe dissipation of electrical surges.

In essence, the holes in US power plugs play a pivotal role in enhancing electrical safety and promoting standardized connectivity. By incorporating these carefully engineered features, power plugs are able to mitigate risks associated with electrical usage, safeguarding both users and connected devices from potential harm. The meticulous design and functionality of these seemingly simple components underscore the intricate considerations involved in the field of electrical engineering, highlighting the intersection of innovation and safety in the realm of power plug design.

The Difference in Plug Sizes Compared to Europe

When comparing power plugs used in the United States to those utilized in Europe, one of the most striking disparities lies in their physical dimensions and configurations. The variation in plug sizes and shapes reflects the diverse electrical standards and infrastructure present in different regions, underscoring the need for compatibility considerations when traveling or utilizing electronic devices across international borders.

In the United States, power plugs typically adhere to the NEMA 1-15 standard, characterized by two flat parallel prongs and, in some cases, a grounding prong. This design is tailored to fit into corresponding power outlets commonly found throughout the country, featuring slots that accommodate the specific dimensions of US power plugs. The compact and streamlined nature of these plugs aligns with the electrical infrastructure and consumer preferences prevalent in the US, emphasizing practicality and ease of use.

On the other hand, European power plugs exhibit a distinct form factor, adhering to various standards such as the Schuko plug used in many European countries. These plugs are characterized by two rounded prongs, often accompanied by a pair of side clips for enhanced stability when inserted into outlets. The larger size and unique shape of European plugs reflect the regional electrical specifications and safety requirements, catering to the nuances of European power systems and infrastructure.

The disparity in plug sizes between the US and Europe necessitates the use of plug adapters or specialized multi-country power strips when traveling between these regions. These adapters serve as intermediary devices, enabling the seamless connection of electronic devices with varying plug configurations to the local power supply. By accommodating the differences in plug sizes and shapes, these adapters facilitate international travel and promote cross-border compatibility, allowing individuals to utilize their electronic devices without encountering compatibility issues.

Furthermore, the divergence in plug sizes underscores the importance of harmonizing international standards and promoting interoperability across different electrical systems. Efforts to establish universal plug designs and compatibility guidelines can streamline global connectivity, simplifying the use of electronic devices in diverse geographical locations and reducing the reliance on specialized adapters.

In essence, the differences in plug sizes between the US and Europe reflect the unique electrical standards and infrastructure present in each region, highlighting the importance of compatibility considerations and the role of adapters in facilitating international connectivity. As technology continues to bridge geographical boundaries, the harmonization of plug designs and standards can contribute to a more seamless and interconnected global electrical landscape.

Conclusion

In conclusion, the intricate design and functionality of power plugs, particularly the purpose of holes in US power plugs and the differences in plug sizes compared to those in Europe, offer valuable insights into the realm of electrical engineering and international standards. The presence of holes in US power plugs serves a critical role in promoting electrical safety, enabling the implementation of polarization and grounding features that mitigate potential hazards and safeguard users and connected devices. These carefully engineered components exemplify the intersection of innovation and safety, underscoring the meticulous considerations involved in power plug design.

Furthermore, the disparities in plug sizes between the US and Europe highlight the diverse electrical standards and infrastructure present in different regions. The distinct physical dimensions and configurations of power plugs reflect the nuanced specifications and safety requirements inherent to each geographical area, emphasizing the need for compatibility considerations when utilizing electronic devices across international borders. The reliance on plug adapters and multi-country power strips underscores the importance of promoting interoperability and harmonizing international standards to facilitate seamless global connectivity.

As technology continues to advance and transcend geographical boundaries, the standardization of plug designs and compatibility guidelines can contribute to a more interconnected global electrical landscape. By fostering a unified approach to power plug design and promoting cross-border compatibility, the industry can enhance user convenience, streamline international travel, and reduce reliance on specialized adapters, ultimately enriching the experience of utilizing electronic devices in diverse geographical locations.

In essence, the purpose of holes in US power plugs and the differences in plug sizes compared to those in Europe encapsulate the multifaceted considerations and implications inherent to power plug design and international electrical standards. By delving into these intricacies, we gain a deeper appreciation for the meticulous engineering behind these seemingly simple yet indispensable components, shedding light on the pivotal role they play in ensuring electrical safety and promoting global connectivity.