Home>Automotive>Unleash The Power: The Surprising Benefits Of Rebuilding Your Alternator!

Automotive

Unleash The Power: The Surprising Benefits Of Rebuilding Your Alternator!

Published: January 6, 2024

Discover the surprising benefits of rebuilding your alternator in the automotive industry. Unleash the power and save money with this insightful guide.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Regretless.com, at no extra cost. Learn more)

Table of Contents

Introduction

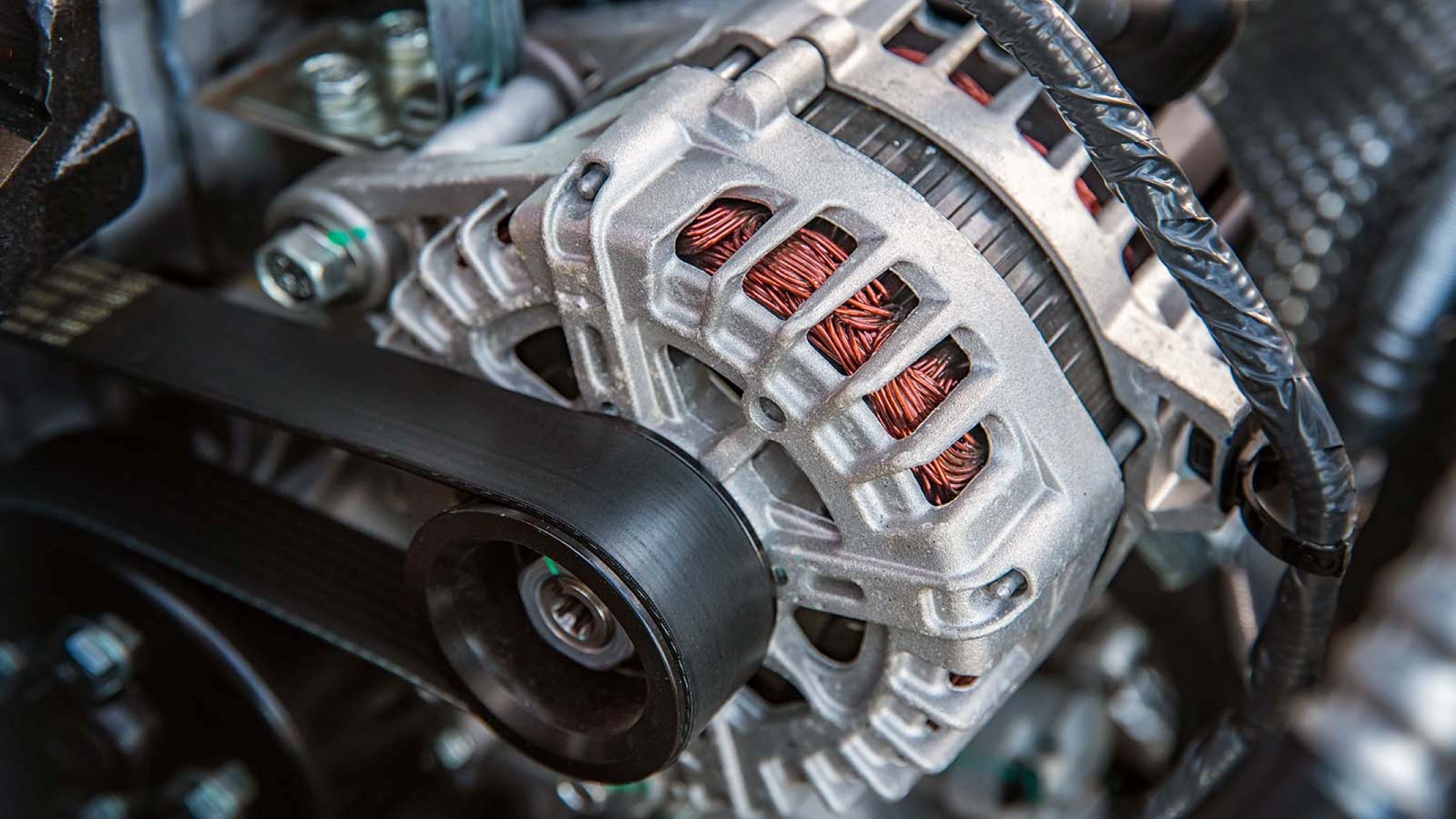

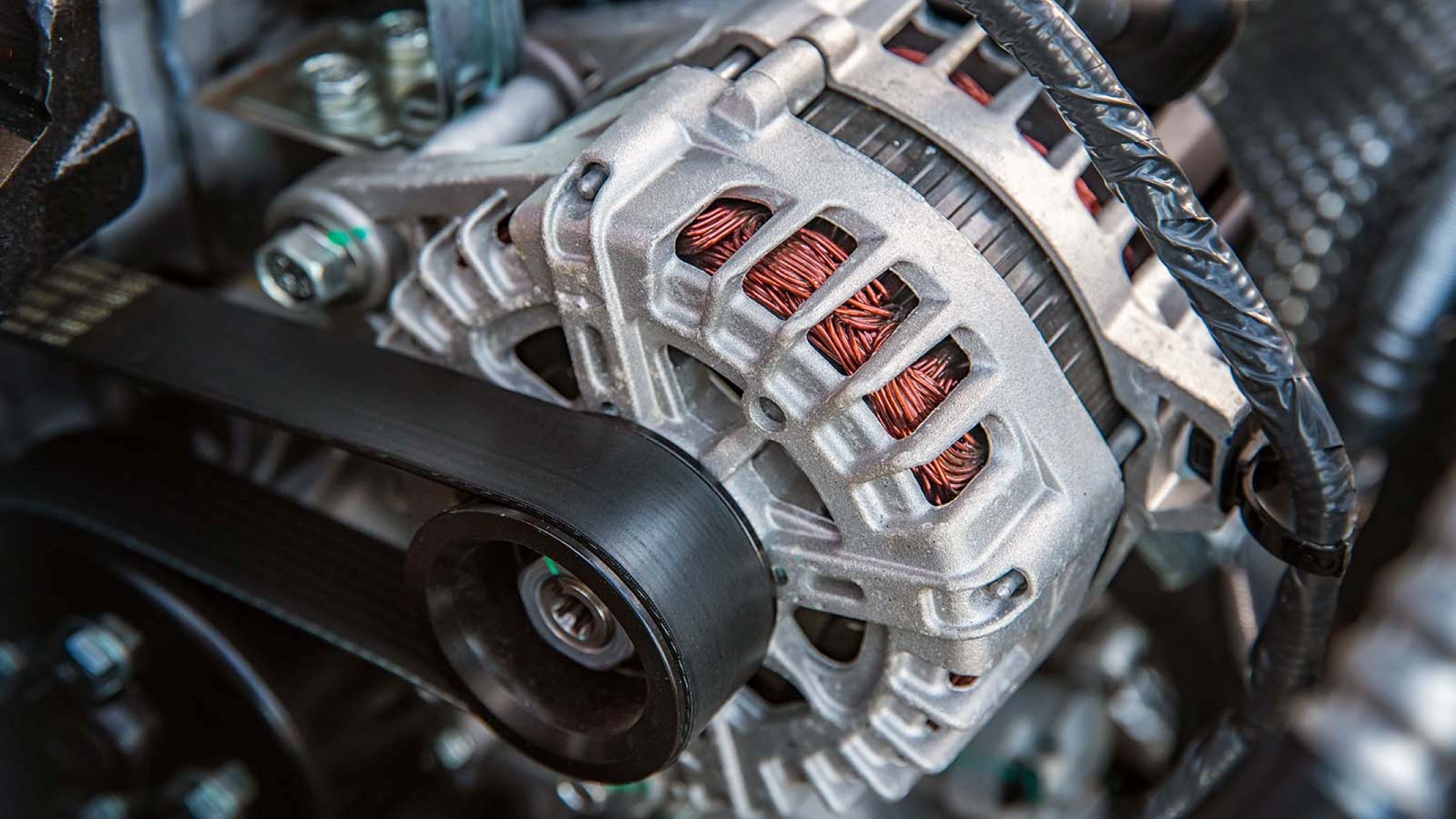

Your vehicle's alternator is a powerhouse, quietly working behind the scenes to keep your car running smoothly. While often overlooked, the alternator plays a pivotal role in powering the electrical systems of your vehicle, including the lights, radio, and crucially, the battery. Understanding the importance of the alternator and its impact on your vehicle's performance is essential for every car owner.

The alternator is a vital component of your vehicle's charging system, responsible for converting mechanical energy into electrical energy. As the engine runs, the alternator generates power to recharge the battery and supply electricity to the various electrical components. Without a functioning alternator, the battery would quickly drain, leaving your vehicle powerless and stranded.

In this article, we will delve into the often underestimated world of alternators, shedding light on the common problems that plague these essential components and exploring the surprising benefits of rebuilding your alternator. Whether you're a seasoned car enthusiast or a novice driver, understanding the inner workings of your vehicle's alternator and the advantages of rebuilding it can empower you to make informed decisions about your car's maintenance and performance.

So, buckle up as we embark on a journey to uncover the hidden potential of your alternator and discover how rebuilding this essential component can breathe new life into your vehicle, save you money, and contribute to a greener, more sustainable automotive future.

Understanding the Alternator

The alternator, a key component of your vehicle's electrical system, serves as a vital source of power generation. As the engine operates, the alternator harnesses mechanical energy and converts it into electrical energy, supplying power to the battery and various electrical components. Unlike the battery, which provides energy to start the engine, the alternator continuously recharges the battery and powers the electrical systems while the vehicle is in motion.

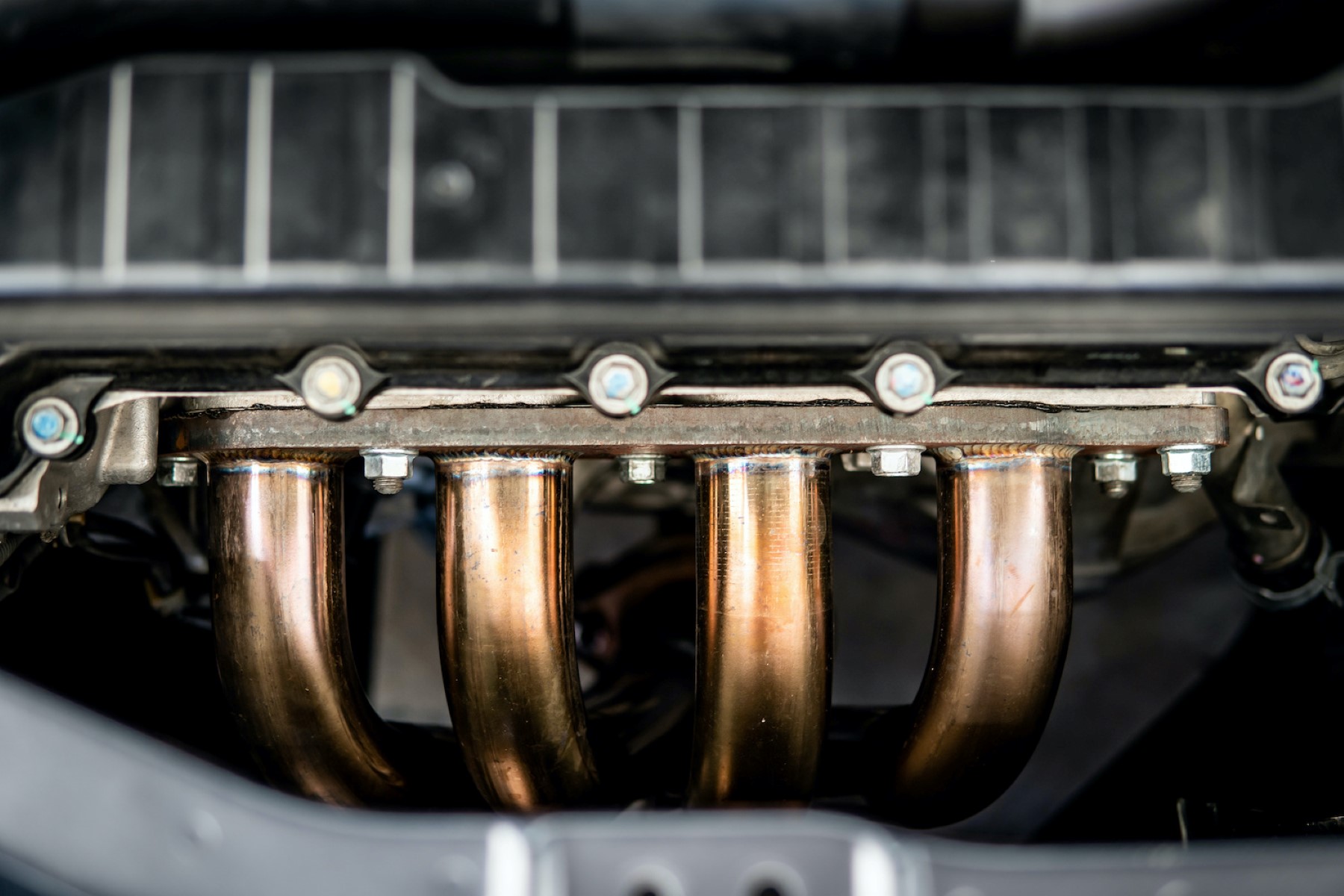

The alternator consists of several essential parts, including a rotor, stator, diode rectifier, voltage regulator, and cooling fan. The rotor, often referred to as the armature, rotates within the stator, which is a stationary set of wire coils. As the rotor spins, it generates a magnetic field within the stator, inducing an alternating current (AC) in the wire coils. The diode rectifier then converts this AC into direct current (DC), which is the type of electricity used by the vehicle's electrical systems. The voltage regulator controls the output of the alternator to ensure a consistent supply of power to the battery and electrical components, while the cooling fan prevents overheating during operation.

The alternator's role in maintaining a healthy electrical system cannot be overstated. It not only powers the headlights, taillights, and interior lights but also facilitates the operation of the air conditioning, radio, power windows, and other electrical accessories. Moreover, the alternator plays a crucial role in ensuring that the battery remains charged, enabling the vehicle to start reliably.

Understanding the alternator's function and components is essential for recognizing the signs of potential issues and addressing them promptly. By grasping the intricacies of this critical component, car owners can make informed decisions about maintenance and repairs, ensuring the longevity and optimal performance of their vehicles.

Common Alternator Problems

The alternator, despite its robust construction and essential role in the vehicle's electrical system, is susceptible to various issues that can compromise its performance. Recognizing common alternator problems is crucial for proactive maintenance and timely repairs, safeguarding the overall functionality of your vehicle.

-

Faulty Voltage Regulator: One of the most prevalent issues with alternators is a malfunctioning voltage regulator. This component regulates the output of the alternator to maintain a consistent voltage supply to the battery and electrical systems. When the voltage regulator fails, it can lead to erratic electrical performance, overcharging or undercharging of the battery, and potential damage to other electrical components.

-

Worn-out Brushes: The alternator contains brushes that maintain electrical contact with the rotor's spinning surface. Over time, these brushes can wear out, leading to poor electrical connection and reduced charging efficiency. Symptoms of worn-out brushes may include dimming lights, electrical system malfunctions, and difficulty starting the vehicle.

-

Bearing Wear: The alternator's rotor spins within the stator with the help of bearings. Continuous use and age can cause these bearings to wear out, resulting in a noisy, grinding sound emanating from the alternator. If left unaddressed, bearing wear can lead to rotor misalignment, increased friction, and ultimately, alternator failure.

-

Slipping or Worn-out Belt: The alternator is driven by a belt connected to the engine's crankshaft. A slipping or worn-out belt can impede the alternator's ability to generate power, leading to reduced charging capacity and potential electrical system failures. Inspecting the belt for signs of wear, cracks, or looseness is essential for maintaining the alternator's functionality.

-

Internal Component Failure: Over time, the internal components of the alternator, including the diode rectifier and stator, can deteriorate due to heat and electrical stress. This can result in erratic charging, electrical system malfunctions, and eventual alternator failure.

Recognizing these common alternator problems and addressing them promptly can prevent costly repairs, unexpected breakdowns, and potential damage to other electrical components in the vehicle. Regular inspection, proactive maintenance, and timely repairs are essential for preserving the reliability and performance of the alternator, ensuring a smooth and trouble-free driving experience.

The Benefits of Rebuilding Your Alternator

Rebuilding your alternator offers a multitude of surprising benefits that extend beyond mere cost savings. It presents an opportunity to breathe new life into a critical component of your vehicle, enhancing its performance, reducing waste, and contributing to a more sustainable automotive ecosystem.

Saving Money

Opting to rebuild your alternator instead of purchasing a new one can lead to substantial cost savings. A rebuilt alternator typically involves replacing worn-out components, such as brushes, bearings, and voltage regulators, while retaining the core housing and other functional parts. This approach not only reduces the environmental impact of manufacturing new units but also offers a more budget-friendly alternative for car owners. By harnessing the expertise of skilled technicians and utilizing high-quality replacement parts, the rebuilding process can restore the alternator to optimal working condition, providing reliable performance at a fraction of the cost of a new unit.

Read more: Unleash The Power Of Flea Traps And Combs For Your Feline Friend – A Safe Alternative To Poison!

Improving Performance

Rebuilding the alternator allows for a comprehensive inspection of its internal components, addressing potential issues that may compromise its performance. By replacing worn-out parts and conducting thorough testing, the rebuilt alternator can deliver enhanced charging efficiency, stable voltage output, and improved reliability. This translates to a more robust electrical system, ensuring consistent power supply to critical vehicle components. Moreover, the meticulous refurbishment process can rectify common alternator problems, such as voltage irregularities and bearing wear, thereby prolonging the lifespan of the alternator and bolstering the overall performance of the vehicle.

Reducing Waste

Choosing to rebuild the alternator aligns with sustainable practices by minimizing waste and reducing the environmental impact of automotive maintenance. Rather than discarding the entire alternator unit, rebuilding salvages functional components and replaces only the necessary parts, reducing the volume of discarded automotive components. This eco-conscious approach contributes to resource conservation and promotes a circular economy within the automotive industry. By extending the lifespan of the alternator through rebuilding, car owners actively participate in reducing the environmental footprint associated with manufacturing and disposing of automotive electrical components.

In essence, rebuilding your alternator transcends the conventional notion of maintenance and repair, offering tangible benefits that encompass financial savings, enhanced performance, and environmental responsibility. Embracing the practice of rebuilding critical vehicle components not only empowers car owners to make cost-effective decisions but also contributes to a more sustainable and eco-friendly automotive landscape.

Saving Money

Opting to rebuild your alternator instead of purchasing a new one presents a compelling opportunity to achieve significant cost savings while contributing to a more sustainable automotive maintenance approach. When considering the financial aspect, the decision to rebuild an alternator is rooted in its potential to deliver reliable performance at a fraction of the cost of acquiring a new unit.

The process of rebuilding an alternator typically involves a comprehensive assessment of its components, identifying and replacing worn-out parts, such as brushes, bearings, and voltage regulators, while retaining the core housing and other functional elements. This meticulous approach to refurbishment not only minimizes waste but also offers a more budget-friendly alternative for car owners.

By harnessing the expertise of skilled technicians and utilizing high-quality replacement parts, the rebuilding process can restore the alternator to optimal working condition, providing reliable performance at a significantly lower cost than purchasing a new unit. This cost-effective strategy aligns with prudent financial management, allowing car owners to allocate their resources efficiently while ensuring the continued functionality of their vehicles' electrical systems.

Furthermore, the decision to rebuild an alternator transcends immediate cost savings, as it also contributes to a more sustainable automotive ecosystem. By opting for rebuilding over replacement, car owners actively participate in reducing the environmental impact associated with manufacturing and disposing of automotive components. This eco-conscious approach aligns with the principles of resource conservation and promotes a circular economy within the automotive industry.

Ultimately, the financial benefits of rebuilding an alternator extend beyond the initial cost savings, encompassing a pragmatic and environmentally responsible approach to vehicle maintenance. Embracing the practice of rebuilding critical vehicle components empowers car owners to make cost-effective decisions while contributing to a more sustainable and eco-friendly automotive landscape.

Improving Performance

Rebuilding the alternator presents a transformative opportunity to elevate the performance and reliability of this critical vehicle component. By embarking on the refurbishment journey, car owners can unlock a myriad of benefits that extend beyond mere cost savings, with a profound impact on the overall functionality of the vehicle's electrical system.

The comprehensive refurbishment process involves a meticulous inspection of the alternator's internal components, allowing for the identification and replacement of worn-out parts that may compromise its performance. This proactive approach addresses potential issues such as faulty voltage regulators, worn-out brushes, bearing wear, and internal component deterioration, which can impede the alternator's charging efficiency and stability.

Through the replacement of worn-out components with high-quality parts and the meticulous testing of the rebuilt alternator, car owners can expect a notable improvement in charging efficiency, stable voltage output, and enhanced reliability. These enhancements translate to a more robust electrical system, ensuring consistent power supply to critical vehicle components and accessories.

Moreover, the refurbishment process can rectify common alternator problems, such as voltage irregularities and bearing wear, thereby prolonging the lifespan of the alternator and bolstering the overall performance of the vehicle. This proactive approach not only enhances the vehicle's reliability but also contributes to a safer and more efficient driving experience.

Furthermore, the rejuvenated alternator, with its improved charging capacity and stable voltage output, plays a pivotal role in sustaining the vehicle's electrical systems, including the headlights, taillights, air conditioning, and other essential accessories. This ensures that the vehicle operates optimally, even under demanding conditions, providing drivers with peace of mind and confidence in their vehicle's performance.

In essence, the process of rebuilding the alternator transcends the realm of traditional maintenance, offering tangible benefits that encompass enhanced performance, extended lifespan, and improved reliability. By investing in the refurbishment of this critical component, car owners can elevate the functionality of their vehicles' electrical systems, ensuring a smoother and more dependable driving experience for miles to come.

Reducing Waste

Rebuilding your alternator is not only a practical and cost-effective choice but also a sustainable practice that contributes to waste reduction and environmental conservation within the automotive industry. By opting to refurbish the alternator instead of replacing it with a new unit, car owners actively participate in minimizing the volume of discarded automotive components, thereby reducing the environmental footprint associated with manufacturing and disposing of electrical parts.

The rebuilding process focuses on salvaging functional components and replacing only the necessary parts, such as brushes, bearings, and voltage regulators, while retaining the core housing and other functional elements. This eco-conscious approach aligns with the principles of resource conservation and promotes a circular economy within the automotive sector. By extending the lifespan of the alternator through rebuilding, car owners play a significant role in minimizing waste generation and preserving valuable resources.

Furthermore, the decision to rebuild the alternator aligns with the broader objectives of sustainable automotive maintenance, emphasizing the importance of prolonging the usability of essential vehicle components. This approach not only reduces the demand for new manufacturing but also minimizes the environmental impact associated with the disposal of old alternators, contributing to a more eco-friendly and responsible automotive ecosystem.

Embracing the practice of rebuilding critical vehicle components, including the alternator, represents a proactive step towards waste reduction and environmental stewardship. By prioritizing refurbishment over replacement, car owners demonstrate a commitment to sustainable practices, fostering a culture of responsible resource management and environmental consciousness within the automotive community.

In essence, reducing waste through the rebuilding of the alternator embodies a holistic approach to vehicle maintenance, integrating economic prudence with environmental responsibility. By choosing to refurbish this essential component, car owners not only benefit from cost savings and improved performance but also actively contribute to the sustainability of the automotive industry, paving the way for a greener and more efficient future.

Conclusion

In conclusion, the alternator stands as a formidable yet often overlooked component within a vehicle's intricate ecosystem. Its role in generating electrical power to sustain the battery and power the various electrical systems is indispensable, underscoring the significance of understanding its inner workings and potential benefits of refurbishment.

The decision to rebuild an alternator presents a compelling array of advantages that extend far beyond financial savings. By opting for refurbishment over replacement, car owners can breathe new life into this critical component, enhancing its performance, reducing waste, and contributing to a more sustainable automotive landscape.

The process of rebuilding an alternator offers a cost-effective alternative, allowing car owners to achieve reliable performance at a fraction of the cost of purchasing a new unit. This prudent financial approach aligns with responsible resource management and empowers individuals to make informed decisions about their vehicle maintenance.

Furthermore, the refurbishment of the alternator transcends immediate cost savings, as it plays a pivotal role in improving the vehicle's overall performance and reliability. Through meticulous inspection, replacement of worn-out components, and comprehensive testing, the rebuilt alternator can deliver enhanced charging efficiency, stable voltage output, and prolonged lifespan, ensuring a more robust electrical system for the vehicle.

Additionally, the practice of rebuilding the alternator embodies a sustainable ethos, contributing to waste reduction and environmental conservation within the automotive industry. By salvaging functional components and replacing only the necessary parts, car owners actively participate in minimizing waste generation and promoting a circular economy, fostering a culture of responsible resource management.

In essence, the decision to rebuild the alternator represents a proactive step towards a more sustainable and eco-friendly automotive future. By embracing the practice of refurbishing critical vehicle components, car owners not only benefit from tangible advantages but also contribute to the broader goal of environmental stewardship and responsible consumption.

As we navigate towards a greener and more efficient automotive landscape, the practice of rebuilding the alternator stands as a testament to the transformative power of sustainable maintenance, offering a compelling model for prudent resource management and environmental consciousness within the automotive community.