Home>Automotive>Understanding The Significance Of A Knocking Sound In An Idle Engine: Is It Universal Or Make And Model Specific?

Automotive

Understanding The Significance Of A Knocking Sound In An Idle Engine: Is It Universal Or Make And Model Specific?

Published: February 18, 2024

Gain insight into the significance of a knocking sound in an idle engine. Discover if it's universal or specific to certain automotive makes and models. Explore potential causes and solutions.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Regretless.com, at no extra cost. Learn more)

Table of Contents

Introduction

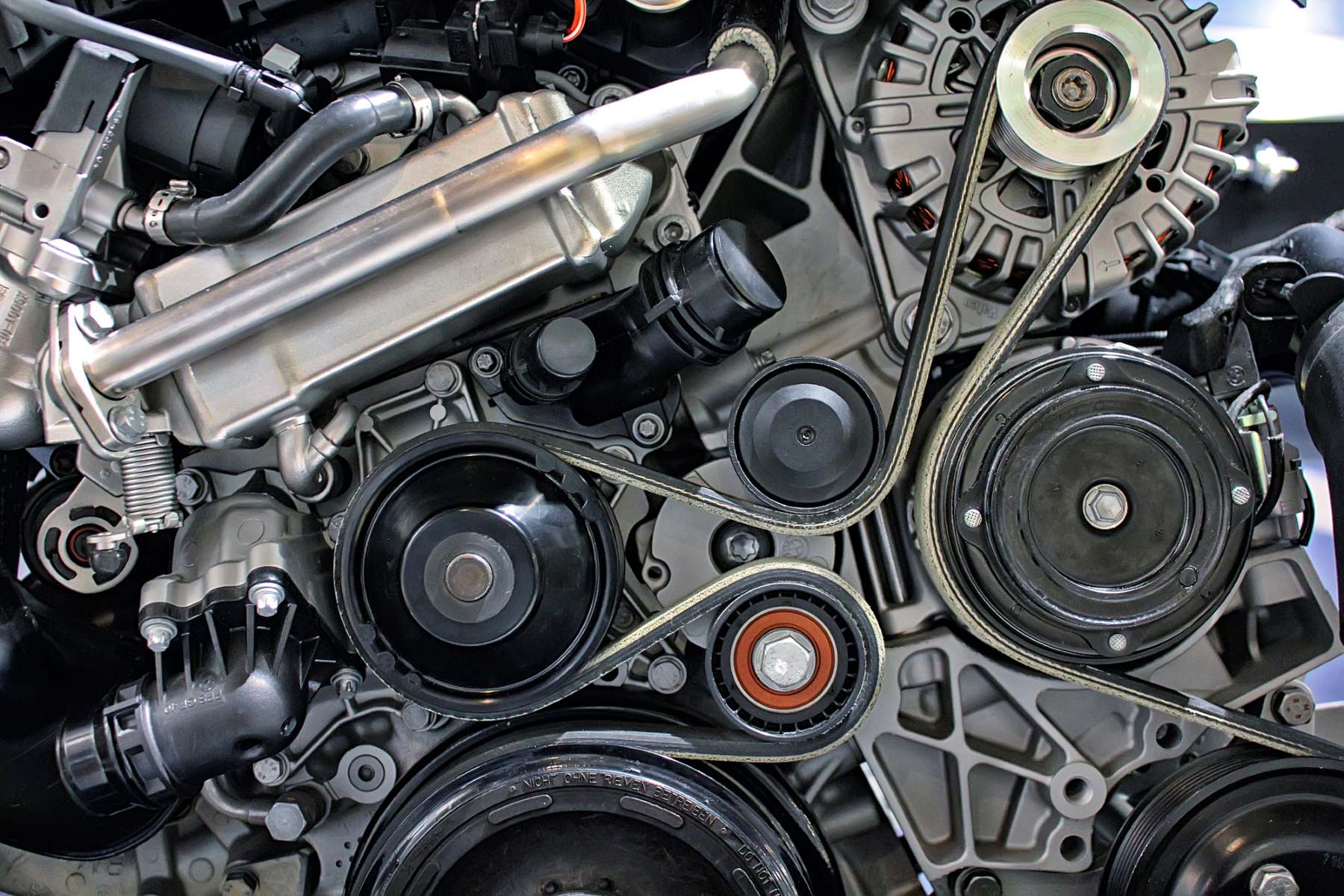

When you start your car and hear an unusual knocking sound emanating from the engine, it can be a cause for concern. Engine knocking, also known as detonation, occurs when the air-fuel mixture in the combustion chamber ignites spontaneously, resulting in a sharp metallic knocking or pinging sound. This phenomenon can be indicative of underlying issues within the engine, and understanding its significance is crucial for maintaining the health and performance of your vehicle.

Engine knocking can be a perplexing occurrence for many drivers, as it often raises questions about its universality across different vehicle makes and models. Is the presence of engine knocking a universal concern, or does it vary based on the specific make and model of the vehicle? These queries underscore the importance of delving into the intricacies of engine knocking to gain a comprehensive understanding of its implications.

In this article, we will explore the physics behind engine knocking, the factors that contribute to this phenomenon, and the potential impact of the make and model of a vehicle on the occurrence of engine knocking. By shedding light on these aspects, we aim to provide valuable insights into the nature of engine knocking and equip readers with the knowledge to identify and address this issue effectively.

As we delve into the complexities of engine knocking, it becomes evident that this phenomenon is not a one-size-fits-all concern. The interplay of various factors, including fuel quality, engine design, and driving conditions, contributes to the occurrence of engine knocking in a manner that can be both universal and make and model specific. By unraveling these intricacies, we can gain a deeper appreciation for the nuances of engine knocking and its implications for different vehicles.

With this in mind, let us embark on a journey to unravel the mysteries of engine knocking, exploring its underlying physics, the diverse factors that influence its occurrence, and the potential variations across different vehicle makes and models. Through this exploration, we aim to empower readers with the knowledge to discern the significance of engine knocking and take proactive measures to ensure the optimal performance and longevity of their vehicles.

Read more: The Surprising Sound Foxes Actually Make!

The Physics of Engine Knocking

Engine knocking, a phenomenon that occurs within the combustion chamber of an internal combustion engine, is rooted in the fundamental principles of thermodynamics and fluid dynamics. At its core, engine knocking is a manifestation of uncontrolled combustion, often triggered by the premature ignition of the air-fuel mixture within the cylinder.

The process of engine knocking unfolds as follows: during the compression stroke of the engine's four-stroke cycle, the air-fuel mixture is compressed by the rising piston, leading to an increase in temperature and pressure within the combustion chamber. Subsequently, the spark plug ignites the compressed mixture at the optimal moment, initiating the power stroke that propels the piston downward. However, in the case of engine knocking, an additional, undesired ignition event occurs before the spark plug's scheduled ignition, giving rise to the characteristic knocking sound.

This premature ignition, known as detonation, can stem from various factors, including high temperatures, excessive cylinder pressure, and the presence of hot spots within the combustion chamber. When these conditions converge, the air-fuel mixture ignites spontaneously, leading to a rapid increase in pressure and temperature that generates shock waves within the cylinder. These shock waves manifest as the distinct knocking sound that reverberates through the engine, signaling the occurrence of uncontrolled combustion.

The physics of engine knocking underscores the delicate balance required for optimal combustion within the engine. Factors such as the air-fuel ratio, ignition timing, and engine temperature play pivotal roles in mitigating the risk of detonation. Additionally, the design and composition of the combustion chamber, as well as the quality of the fuel used, can significantly influence the propensity for engine knocking.

Understanding the physics of engine knocking provides valuable insights into the intricate interplay of variables that govern combustion within the engine. By delving into the underlying principles of thermodynamics and fluid dynamics, we can appreciate the nuanced factors that contribute to the occurrence of engine knocking, laying the groundwork for addressing this phenomenon effectively.

As we unravel the physics of engine knocking, it becomes evident that this phenomenon is not merely a random occurrence but rather a manifestation of the intricate dynamics at play within the heart of the engine. By gaining a deeper understanding of these underlying principles, we can equip ourselves with the knowledge to identify, mitigate, and prevent engine knocking, thereby safeguarding the optimal performance and longevity of our vehicles.

Factors Contributing to Engine Knocking

Several interrelated factors contribute to the occurrence of engine knocking, encompassing a diverse array of variables that can influence the combustion process within the engine. Understanding these factors is pivotal in discerning the root causes of engine knocking and implementing effective measures to mitigate its impact. Let's delve into the multifaceted elements that contribute to this phenomenon:

1. Fuel Quality:

The quality and composition of the fuel used in an internal combustion engine play a critical role in determining the propensity for engine knocking. Lower octane-rated fuels are more prone to premature ignition, leading to increased instances of detonation. Additionally, the presence of impurities or contaminants in the fuel can exacerbate the risk of engine knocking, underscoring the significance of utilizing high-quality, clean fuels to minimize this phenomenon.

2. Ignition Timing:

The precise timing of the spark plug's ignition is a key determinant of combustion efficiency within the engine. Deviations from the optimal ignition timing can result in premature ignition of the air-fuel mixture, giving rise to engine knocking. Factors such as worn timing components or incorrect adjustments can disrupt the ignition timing, necessitating meticulous calibration to mitigate the risk of detonation.

3. Engine Temperature:

Elevated engine temperatures can contribute to the occurrence of engine knocking, as excessive heat within the combustion chamber can promote spontaneous ignition of the air-fuel mixture. Inadequate cooling systems, prolonged high-load operation, or insufficient lubrication can elevate engine temperatures, heightening the likelihood of detonation. Maintaining optimal engine cooling and lubrication is essential in mitigating the impact of high temperatures on engine knocking.

4. Air-Fuel Ratio:

The ratio of air to fuel within the combustion chamber significantly influences the combustion process. A lean air-fuel mixture, characterized by an excess of air relative to fuel, can increase the susceptibility to engine knocking. Conversely, a rich mixture, with an abundance of fuel, can also impact combustion dynamics, underscoring the delicate balance required to minimize the risk of detonation.

5. Cylinder Pressure:

Excessive cylinder pressure, often stemming from aggressive engine tuning or forced induction systems, can elevate the likelihood of engine knocking. The heightened pressure within the combustion chamber can expedite the onset of detonation, necessitating meticulous calibration of engine parameters to optimize cylinder pressure and mitigate the risk of knocking.

By comprehensively examining these factors, we gain a holistic understanding of the intricate variables that contribute to engine knocking. The interplay of fuel quality, ignition timing, engine temperature, air-fuel ratio, and cylinder pressure underscores the multifaceted nature of this phenomenon, highlighting the need for meticulous attention to these factors to minimize the risk of engine knocking and preserve the optimal performance of the engine.

The Impact of Make and Model on Engine Knocking

The impact of the make and model of a vehicle on the occurrence of engine knocking is a multifaceted aspect that intertwines engineering intricacies, design variations, and performance characteristics. Different vehicle manufacturers employ diverse engineering approaches, fuel delivery systems, and combustion chamber designs, all of which can influence the propensity for engine knocking. Additionally, the specific performance attributes and intended applications of various vehicle models can contribute to variations in the occurrence of engine knocking across different makes and models.

The make and model of a vehicle can significantly influence the likelihood of engine knocking due to variations in engine design, compression ratios, and fuel management systems. For instance, high-performance vehicles often feature aggressive engine tuning, elevated compression ratios, and advanced fuel delivery systems aimed at maximizing power output. While these attributes enhance performance, they can also elevate the risk of engine knocking under certain operating conditions, especially when subjected to high loads or extreme temperatures.

Furthermore, the design of the combustion chamber, piston geometry, and intake/exhaust configurations can vary between different vehicle makes and models, impacting the dynamics of combustion and the susceptibility to engine knocking. These design disparities can manifest in distinct combustion characteristics, thermal profiles, and turbulence within the combustion chamber, all of which can influence the occurrence of detonation.

In addition to design variations, the intended application of a vehicle can also play a pivotal role in determining the likelihood of engine knocking. Vehicles designed for towing, hauling, or high-performance driving may exhibit different tendencies toward engine knocking compared to those engineered for fuel efficiency and everyday commuting. The operational demands placed on the engine, such as sustained high loads or frequent high-speed driving, can accentuate the risk of detonation, thereby amplifying the impact of make and model on the occurrence of engine knocking.

Moreover, the fuel requirements and compatibility of different vehicle makes and models can contribute to variations in the susceptibility to engine knocking. Certain vehicles may necessitate higher octane-rated fuels to mitigate the risk of detonation, while others may exhibit greater tolerance to lower octane fuels due to optimized combustion characteristics. These distinctions underscore the nuanced interplay between vehicle make, model, and fuel considerations in shaping the propensity for engine knocking.

By delving into the impact of make and model on engine knocking, we gain a deeper appreciation for the diverse factors that contribute to this phenomenon across different vehicles. The intricate interplay of engineering nuances, performance attributes, and operational considerations underscores the need for tailored approaches to address and mitigate the impact of engine knocking based on the specific make and model of the vehicle.

This comprehensive understanding empowers drivers and automotive enthusiasts to discern the implications of make and model on engine knocking, enabling them to make informed decisions regarding fuel selection, maintenance practices, and driving behaviors to safeguard the optimal performance and longevity of their vehicles.

Universal Causes of Engine Knocking

Universal causes of engine knocking encompass a range of factors that transcend specific vehicle makes and models, exerting a pervasive influence on the propensity for detonation across diverse automotive platforms. These universal causes underscore the fundamental principles and variables that govern combustion dynamics within internal combustion engines, shedding light on the shared vulnerabilities to engine knocking irrespective of the vehicle's engineering intricacies.

-

Fuel Quality: The quality of fuel, particularly the octane rating, stands as a universal determinant of engine knocking. Lower octane fuels are inherently more prone to premature ignition, amplifying the risk of detonation across a broad spectrum of vehicles. This universal susceptibility underscores the critical role of utilizing high-quality, appropriately rated fuels to mitigate the impact of engine knocking.

-

Ignition Timing: The precise timing of the spark plug's ignition, a fundamental aspect of combustion control, holds universal significance in the context of engine knocking. Deviations from optimal ignition timing can precipitate detonation, transcending the boundaries of specific vehicle makes and models. Meticulous calibration of ignition timing stands as a universal imperative to minimize the risk of engine knocking.

-

Engine Temperature: Elevated engine temperatures, a pervasive consequence of sustained high loads or inadequate cooling, universally elevate the likelihood of engine knocking. The universal impact of engine temperature on detonation underscores the imperative of robust cooling systems and vigilant temperature management to mitigate the risk of knocking across diverse vehicles.

-

Air-Fuel Ratio: The universal influence of air-fuel ratio on engine knocking is rooted in the fundamental principles of combustion dynamics. Whether in high-performance vehicles or everyday commuter cars, the delicate balance of air and fuel within the combustion chamber universally shapes the susceptibility to detonation. Maintaining optimal air-fuel ratios emerges as a universal strategy to mitigate the impact of engine knocking.

-

Cylinder Pressure: Excessive cylinder pressure, stemming from aggressive engine tuning or forced induction systems, universally heightens the risk of engine knocking. This universal vulnerability underscores the need for meticulous calibration of engine parameters to optimize cylinder pressure and minimize the universal impact of knocking across diverse vehicle platforms.

By delineating these universal causes of engine knocking, we gain a comprehensive understanding of the shared vulnerabilities that transcend specific vehicle makes and models. The universal nature of these causes underscores the need for proactive measures, such as fuel selection, ignition timing calibration, temperature management, and air-fuel ratio optimization, to universally mitigate the impact of engine knocking and preserve the optimal performance of internal combustion engines across the automotive spectrum.

Conclusion

In conclusion, the significance of a knocking sound in an idle engine extends beyond a mere auditory nuisance, serving as a potent indicator of underlying issues within the heart of the vehicle. Through our exploration of the physics of engine knocking, the multifaceted factors contributing to this phenomenon, and the potential impact of the make and model on its occurrence, we have gained valuable insights into the complexities of this pervasive concern.

The intricate interplay of thermodynamics, fluid dynamics, and combustion dynamics underscores the delicate balance required for optimal combustion within the engine. Factors such as fuel quality, ignition timing, engine temperature, air-fuel ratio, and cylinder pressure collectively shape the propensity for engine knocking, highlighting the need for meticulous attention to these variables to mitigate the risk of detonation.

Moreover, the impact of the make and model of a vehicle on engine knocking unveils a tapestry of engineering nuances, design variations, and performance attributes that influence the occurrence of detonation. The diverse combustion chamber designs, compression ratios, fuel management systems, and operational demands across different vehicle makes and models underscore the need for tailored approaches to address and mitigate the impact of engine knocking based on specific vehicle characteristics.

Furthermore, the universal causes of engine knocking, encompassing fuel quality, ignition timing, engine temperature, air-fuel ratio, and cylinder pressure, transcend the boundaries of specific vehicle makes and models, exerting a pervasive influence on the propensity for detonation across diverse automotive platforms. This universality underscores the imperative of proactive measures, such as fuel selection, ignition timing calibration, temperature management, and air-fuel ratio optimization, to universally mitigate the impact of engine knocking and preserve the optimal performance of internal combustion engines.

By unraveling the mysteries of engine knocking and delving into its implications for different vehicles, we have equipped ourselves with the knowledge to discern the significance of this phenomenon and take proactive measures to ensure the optimal performance and longevity of our vehicles. As we navigate the intricate dynamics of engine knocking, this comprehensive understanding empowers us to make informed decisions regarding fuel selection, maintenance practices, and driving behaviors, thereby safeguarding the health and efficiency of our vehicles.

In essence, the significance of a knocking sound in an idle engine transcends the realm of mere noise, serving as a gateway to a deeper understanding of the intricate dynamics at play within the heart of the vehicle. By embracing this understanding and leveraging it to implement proactive measures, we can navigate the complexities of engine knocking with confidence, ensuring the optimal performance and longevity of our cherished vehicles.