Home>Automotive>The Surprising Reason Your Car Sputters After Refueling

Automotive

The Surprising Reason Your Car Sputters After Refueling

Published: January 20, 2024

Discover the surprising reason why your car sputters after refueling and how to fix it. Get expert automotive advice and troubleshooting tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Regretless.com, at no extra cost. Learn more)

Table of Contents

Introduction

Have you ever experienced a peculiar sputtering sensation in your car immediately after refueling? It's a common scenario that often leaves drivers perplexed. The sudden stuttering and hesitation in the engine's performance can be quite disconcerting, especially when you're eager to hit the road with a full tank of gas. However, there's a surprising reason behind this phenomenon that many drivers are unaware of.

In this article, we'll delve into the intricate workings of your car's fuel system to uncover the mystery behind the post-refueling sputtering. By understanding the underlying mechanisms at play, you'll gain valuable insights into how the refueling process can impact your vehicle's performance. Moreover, we'll explore the concept of vapor lock and its pivotal role in causing sputtering after refueling.

So, fasten your seatbelt and get ready to embark on a fascinating journey through the inner workings of your car's fuel system. By the end of this article, you'll not only comprehend the surprising reason behind the post-refueling sputtering but also learn valuable tips to prevent this inconvenience in the future. Let's dive in and unravel the intriguing connection between refueling and your car's performance!

Understanding the Fuel System

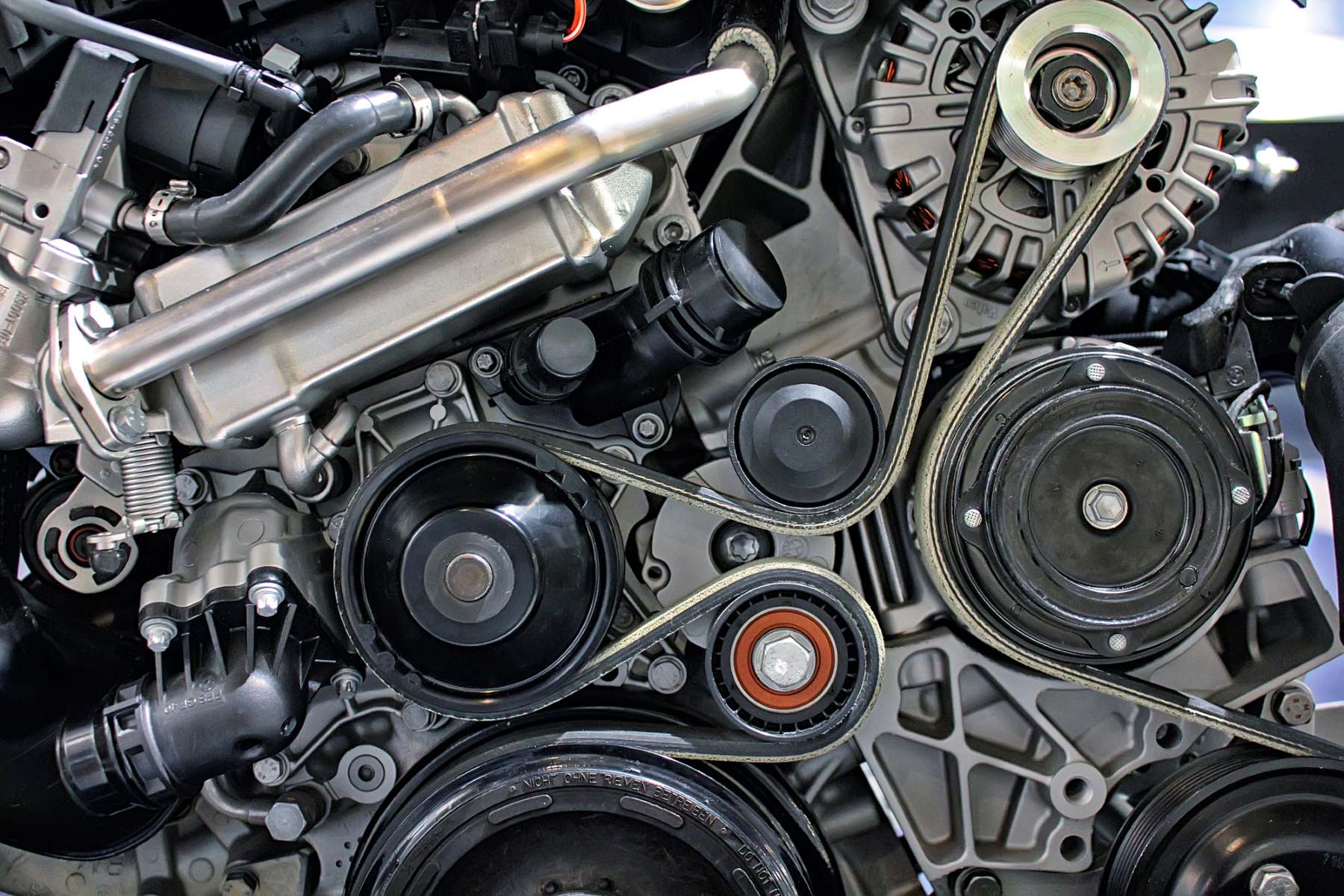

The fuel system of a vehicle is a complex network of components designed to deliver fuel from the tank to the engine, ensuring optimal combustion and power generation. At the heart of this system is the fuel tank, which stores the gasoline or diesel required to propel the vehicle. Connected to the fuel tank is the fuel pump, a crucial component responsible for drawing fuel from the tank and delivering it to the engine.

Once the fuel is pumped from the tank, it travels through fuel lines to the engine's fuel injectors, which are tasked with precisely spraying the fuel into the combustion chambers. The fuel injectors play a pivotal role in ensuring the proper air-fuel mixture for combustion, thereby influencing the engine's performance and efficiency.

Moreover, modern vehicles are equipped with a fuel pressure regulator, which maintains a consistent fuel pressure within the system to optimize engine operation. This component is essential for achieving the right balance of fuel delivery, especially during acceleration and deceleration.

Additionally, the fuel system incorporates a fuel filter to strain out impurities and contaminants that may have entered the tank. By preventing these particles from reaching the engine, the fuel filter safeguards the delicate components of the fuel injection system, promoting longevity and reliability.

Furthermore, the engine control unit (ECU) or engine control module (ECM) plays a crucial role in monitoring and adjusting the fuel delivery process. It continuously analyzes various parameters, such as engine speed, load, and temperature, to optimize the fuel injection timing and duration, thereby ensuring efficient combustion and power generation.

In essence, the fuel system is a sophisticated network of components that work in harmony to deliver the precise amount of fuel required for optimal engine performance. Understanding the intricate interplay of these components is paramount for comprehending how the refueling process can impact the vehicle's operation, particularly in relation to the occurrence of sputtering after refueling.

The Impact of Refueling on the Fuel System

When you pull into a gas station and begin refueling your vehicle, you might not realize the potential impact this seemingly routine task can have on your car's intricate fuel system. The refueling process introduces several factors that can influence the functionality of the fuel system, ultimately affecting the engine's performance.

Firstly, as you begin refueling, the sudden influx of fuel into the tank can agitate any sediment or impurities settled at the bottom. These particles, if disturbed, can potentially clog the fuel filter or make their way into the fuel lines, affecting the flow of fuel to the engine. This disruption can lead to irregular fuel delivery, impacting the combustion process and subsequently causing sputtering and hesitation in the engine's operation.

Moreover, the act of refueling often involves the removal and replacement of the fuel tank cap. This seemingly innocuous action can inadvertently introduce moisture into the fuel system. When the fuel tank cap is removed, especially in humid or rainy conditions, moisture-laden air can enter the tank. Over time, this moisture can accumulate and mix with the fuel, potentially leading to issues such as corrosion within the fuel system components or disruption of the fuel-air mixture, resulting in engine sputtering and reduced performance.

Furthermore, the refueling process itself can inadvertently trigger the activation of the vehicle's evaporative emissions control system. This system is designed to capture and contain fuel vapors, preventing their release into the atmosphere. However, during refueling, the sudden increase in fuel volume can lead to a surge of vapors within the system. If the evaporative emissions control system is not functioning optimally, this surge of vapors can disrupt the air-fuel balance in the engine, leading to momentary sputtering as the system adjusts to the influx of vapors.

In essence, while refueling is a necessary and routine aspect of vehicle ownership, it is important to recognize its potential impact on the fuel system. By understanding the implications of refueling, drivers can take proactive measures to minimize the likelihood of post-refueling sputtering and maintain the optimal performance of their vehicles.

The Role of Vapor Lock in Sputtering

Vapor lock is a phenomenon that can significantly contribute to the sputtering experienced by vehicles after refueling. To understand vapor lock, it's essential to delve into the intricacies of the fuel system and the impact of temperature on fuel properties.

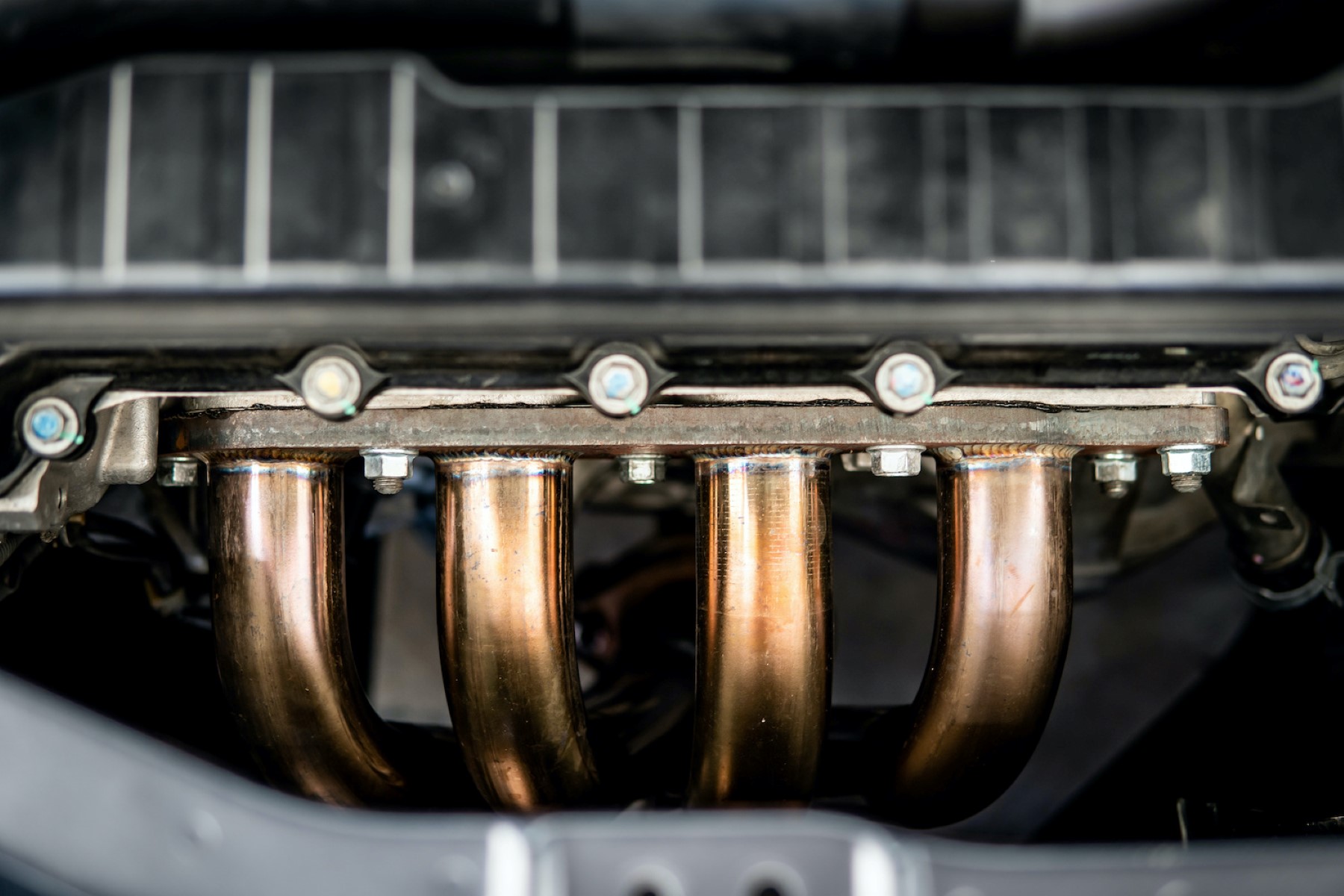

In a typical fuel system, the fuel pump is responsible for drawing fuel from the tank and delivering it to the engine. However, under certain conditions, such as high ambient temperatures, the fuel in the lines leading to the engine can undergo a phase change and transform into vapor. This vaporization can occur due to the heat absorbed from the surrounding environment or from the engine itself, especially in close proximity to hot components.

When vaporization occurs within the fuel lines, it can lead to the formation of vapor pockets or bubbles, obstructing the flow of liquid fuel to the engine. This disruption in fuel delivery can cause momentary sputtering and hesitation in the engine's operation, as the combustion process is compromised by the inadequate supply of fuel.

Furthermore, vapor lock can be exacerbated by the design and layout of the vehicle's fuel system. In some instances, fuel lines may be routed in close proximity to hot engine components or exhaust systems, further increasing the likelihood of vapor formation. Additionally, older vehicles or those with less sophisticated fuel systems may be more susceptible to vapor lock, as they may lack adequate insulation or vapor containment measures.

The occurrence of vapor lock is particularly pronounced immediately after refueling. When the fuel tank is replenished, the introduction of cooler fuel can cause a rapid temperature change within the fuel lines. This abrupt transition can create conditions conducive to vapor formation, especially if the ambient temperature is high. As a result, the engine may experience sputtering and momentary power loss as it grapples with the effects of vapor lock.

To mitigate the impact of vapor lock on post-refueling sputtering, it's essential to implement preventive measures. Ensuring proper insulation and routing of fuel lines, especially away from heat sources, can minimize the likelihood of vapor formation. Additionally, maintaining the evaporative emissions control system in optimal condition is crucial, as it helps manage fuel vapors and reduce the risk of vapor lock-induced sputtering.

By understanding the role of vapor lock in post-refueling sputtering, drivers can appreciate the intricate interplay between temperature, fuel properties, and the design of the fuel system. Armed with this knowledge, they can take proactive steps to minimize the impact of vapor lock and ensure a smoother and more consistent driving experience after refueling.

Preventing Sputtering After Refueling

Preventing sputtering after refueling involves proactive measures aimed at minimizing the potential disruptions to the fuel system and engine operation. By implementing these preventive strategies, drivers can mitigate the likelihood of experiencing post-refueling sputtering and ensure a smoother transition back onto the road.

-

Selecting Reputable Fuel Stations: Choosing reputable and well-maintained fuel stations can significantly reduce the risk of encountering contaminated or low-quality fuel. Stations with regular maintenance and quality control measures in place are more likely to provide clean and uncontaminated fuel, minimizing the possibility of sediment or impurities entering the fuel system during refueling.

-

Avoiding Overfilling the Tank: Overfilling the fuel tank can lead to the inadvertent introduction of fuel into the evaporative emissions control system, potentially causing disruption and triggering the emission of excess vapors. By avoiding overfilling, drivers can prevent the unnecessary introduction of fuel into the emissions control components, reducing the risk of vapor-related sputtering.

-

Replacing the Fuel Cap Correctly: After refueling, ensuring that the fuel tank cap is securely and correctly replaced is crucial. A properly sealed fuel cap helps maintain the integrity of the fuel system, preventing the entry of moisture and minimizing the risk of corrosion or fuel contamination. Additionally, a secure fuel cap assists in managing the pressure within the fuel tank, contributing to the overall stability of the system.

-

Maintaining the Evaporative Emissions Control System: Regular inspections and maintenance of the vehicle's evaporative emissions control system are essential for preventing post-refueling sputtering. Ensuring that the system's components, such as the charcoal canister and purge valve, are functioning optimally can help manage fuel vapors effectively, reducing the likelihood of vapor-related disruptions to the engine's operation.

-

Monitoring Fuel Quality: Being mindful of the quality of fuel being dispensed into the vehicle is crucial for preventing sputtering after refueling. While it may not always be possible to ascertain the exact quality of the fuel, selecting reputable and well-established fuel stations can provide a degree of assurance regarding the fuel's cleanliness and adherence to quality standards.

-

Addressing Fuel System Maintenance: Regular maintenance of the vehicle's fuel system, including the fuel filter, fuel lines, and fuel injectors, is vital for preventing post-refueling sputtering. Ensuring that these components are clean and free from obstructions can promote consistent fuel delivery to the engine, minimizing the risk of sputtering and hesitation.

By incorporating these preventive measures into their refueling routine and overall vehicle maintenance, drivers can proactively reduce the likelihood of experiencing sputtering after refueling, fostering a more seamless and enjoyable driving experience.

Conclusion

In conclusion, the seemingly perplexing occurrence of sputtering after refueling can be attributed to a confluence of factors within the vehicle's fuel system. Understanding the intricate interplay of these elements sheds light on the surprising reasons behind this phenomenon and equips drivers with valuable insights to mitigate its impact.

The refueling process, while essential for keeping vehicles in motion, introduces potential disruptions to the fuel system. From the agitation of sediment in the tank to the inadvertent introduction of moisture and the activation of the evaporative emissions control system, refueling can set the stage for post-refueling sputtering. Moreover, the role of vapor lock, influenced by temperature and fuel properties, emerges as a significant contributor to the engine's momentary hesitation and power loss.

However, armed with this understanding, drivers can implement preventive measures to minimize the likelihood of experiencing sputtering after refueling. Selecting reputable fuel stations, avoiding overfilling the tank, and ensuring the correct replacement of the fuel cap are proactive steps that can safeguard the integrity of the fuel system. Additionally, maintaining the evaporative emissions control system and monitoring fuel quality are crucial aspects of preventive maintenance that contribute to a smoother post-refueling experience.

By integrating these preventive strategies into their refueling routine and overall vehicle maintenance, drivers can navigate the potential pitfalls associated with post-refueling sputtering. Through a combination of awareness, diligence, and proactive measures, they can enhance the reliability and performance of their vehicles, ensuring a seamless transition back onto the road after refueling.

In essence, the surprising reason behind your car's sputtering after refueling is intricately linked to the dynamics of the fuel system and the subtle influences of the refueling process. By unraveling this mystery, drivers can empower themselves to take control of their vehicle's performance, fostering a more consistent and enjoyable driving experience.